They are designed to heat and automatically maintain the desired temperature of natural gas before throttling at gas distribution plants, gas-compressor stations of main gas pipelines and other warm gas consumers in order to increase the reliability of the processing equipment.

Currently a new line of gas heaters with intermediate heat medium "Fakel" PG-1", "Fakel" PG-3", "Fakel" PG-5", "Fakel" PG-10", "Fakel" PG-15", "Fakel" PG-30", "Fakel" PG-50", was developed . The new type of heaters differs essentially from its predecessors in reliability, energy efficiency, higher level of automation, reduced weight and size and reduced amount of used heat-transfer medium.

Specification comparison

| № |

Name of the main indicators |

Gas heater with intermediate heat medium "Fakel-PG-1» |

Gas heater with intermediate heat medium "Fakel-PG-3» |

Gas heater with intermediate heat medium "Fakel-PG-5» |

Gas heater with intermediate heat medium "Fakel-PG-10 |

Gas heater with intermediate heat medium "Fakel-PG-15» |

Gas heater with intermediate heat medium "Fakel-PG-30» |

Gas heater with intermediate heat medium "Fakel-PG-50» |

| 1 |

Specifications |

TU U 29.2-04601469-053:2011 |

TU U 29.2-04601469-053:2011 |

TU U 29.2-04601469-053:2011 |

TU U 29.2-04601469-053:2011 |

TU U 29.2-04601469-053:2011 |

TU U 29.2-04601469-053:2011 |

TU U 29.2-04601469-053:2011 |

| 2 |

Rated gas treatment capacity, not less than, Nm3/h |

1 000 |

3 000 |

5 000 |

10 000 |

15 000 |

30 000 |

50 000 |

| 3 |

Gas pressure at the inlet, Mpa |

7,35 |

7,35 |

7,35 |

7,35 |

7,35 |

7,35 |

7,35 |

| 4 |

Gas flow to the burner at nominal capacity, Nm3/h |

2,3 |

6,7 |

10,8 |

24 |

40 |

70 |

130 |

| 5 |

Efficiency coefficient of the heater, not less than, % |

92 |

92 |

92 |

92 |

92 |

92 |

92 |

| 6 |

Nominal electrical power consumed, W |

100 |

150 |

150 |

150 |

150 |

150 |

350 |

| 7 |

Amount of heat-transfer medium, l |

170 |

450 |

900 |

900 |

1300 |

3050 |

3500 |

| 8 |

Dimensions, LxHxW (without flue gas duct and flares), mm |

1650х1550х1100 |

2350х1550х1150 |

3010х1850х1420 |

3175х1850х1420 |

3750х2000х1450 |

4650х1790х2300 |

5500х1800х2450 |

| 9 |

Heater weight (without heat-transfer medium), not more than, kg |

600 |

1000 |

1600 |

2050 |

2350 |

5200 |

6200 |

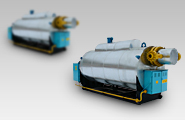

Gas heaters with intermediate heat medium

Fakel" PG-1", "Fakel" PG-3", "Fakel" PG-5", "Fakel" PG-10", "Fakel" PG-15", "Fakel" PG-30", "Fakel" PG-50"

Advantages over similar products

The gas heaters with intermediate heat medium allow to save gas for in-house needs, reduce the environmental load, and are used in renovation, modernization and construction of new facilities.

Advantages in comparison with similar products:

- the construction of shell of the gas heater has been redesigned allowing to increase the heat transfer intensity inside the shell and enhances the efficiency coefficient (EC) of gas heater;

- heat exchanger has been redesigned;

- the efficiency coefficient has been increased to a minimum of 92%, which reduces the gas consumption for in-house needs;

- the application of control complex for gas heater "Gas Heater Control" allows for fine adjustment of the combustion process and the mode of operational shutdown allowing to use the fuel gas more efficiently. The complex can be used both with stepless and discrete adjustment of fuel gas to the burner assembly;

- the weight and size of the heaters have been reduced, resulting in significant reduction of amount of required heat-transfer medium which reduces operating costs and allows to bring the heater to operating condition in a shorter period of time;

- the heat-exchange surface of the gas heaters is designed for heating the gas with temperature drop from minus 15 to plus 35 °C at nominal capacity;

- commercial recording of gas consumption is used;

- looks aesthetically pleasing when container is used;

- the heat exchange process has been intensified;

- thermal expansion absorber has been installed.

.jpg)